Torlon®/Vacuum Pump Vanes

Rotary vacuum pumps, developing up to 300 cfm at 15" hg, drive large scale dairy parlors, food processing facilities, waste treatment plants and other applications requiring stable, high output vacuum.

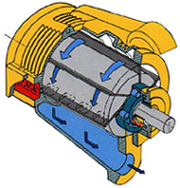

In rotary vacuum pumps, sliding vanes set in slots in a rotating shaft are forced outward against the housing by centrifugal force to create vacuum. The seal of the vanes to the curvature and the butt ends of the housing determines the efficiency of the pump. As vanes wear and/or warp, gaps in the seal can occur reducing vacuum efficacy, and the vanes must be replaced.

Torlon vanes are optimally suited to exposure to the constant high rpm friction, heat and oil in rotary vacuum pumps. The material has one of the lowest coefficients of friction of any material (in both lubricated and non-lubricated environments). It has a continuous use temperature of 275°C, excellent chemical resistance, and high impact and tensile strength.

Torlon vanes improve efficiency and longevity allowing pumps to maintain optimum vacuum output and extending the interval between replacements. Torlon has several advantages over fabric/phenolic vanes.