Engineering Polymers/Overview

HPP's and ETP's

High performance thermoplastics (HPTP) are characterized by extremely high heat tolerance (CUT to 300°C; melt temperatures to 400°C) in combination with two or more other exceptional properties, such as enhanced chemical resistance, near steel like strength, significant flame retardant properties, remarkably low friction coefficients etc. These exceptional properties are reflected in the higher cost for HPP's.

Engineering polymers (ETP) feature mid-range temperatures (CUT to 120°C; melt temperatures to 270°C) and the presence of one or two mechanical properties, such as stiffness, toughness, and low creep that make them valuable in the manufacture of structural products like gears, bearings, electronic devices, and auto parts. EPT's are cost effective in many applications.

An Expanded Arsenal

Engineering polymers, with specificity of properties and lower costs than HPP's, provide China Array's engineers with an expanded arsenal of materials for finding the best balance of price and performance for applications.

ABS

At the beginning of the performance range of ETPs may be found materials such as acrylic and an acrylic copolymer engineered for toughness known as ABS, short for Acrylinitrile-Butadene-Styrene (CUT's of 85°C; melt temperatures of 225°C).

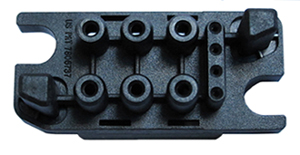

Polybutylene Terephthalate (PBT)

PBT's high crystallinity translates to low polarity and water absorption, plus excellent chemical resistance particularly to organic solvents.

At temperatures below 130°F, PBT exhibits fine wear resistance and stable electrical properties making it a practical, economical choice for such applications as connector housing. PBT takes fillers and additives well, and it can be dyed.

Polycarbonate (PC)

A popular polymer with 4.3 million metric tons consumed annually, polycarbonate is naturally transparent, yet highly impact resistant (one application is bullet proof glass). It is tough, heat resistance, and has excellent dimensional and color stability.

PC, an amorphous material, also lends itself well to compounding and coating, which allows other properties to be blended with those inherent to PC.

Nylon

Unlike polycarbonate, nylon is crystalline in nature; so the molecular chains do not have large substituent groups (such as the phenyl ring in polycarbonate). The crystalline nature of the material is responsible for its wear resistance, chemical resistance, thermal resistance, and higher mold shrinkage.

Optical Molding: Zeonex® (Cyclo Olefin Polymer)

China Array molds Zeonex® for an underwater dome application. Strong enough to resist underwater pressures, Zeonex® offers high transparency (92% in visible range 400-800nm), high purity and lower fluorescence than polycarbonate or polysulfone. Additionally, the material has low moisture absorption (less than 0.01%), heat resistance to 160°C and chemical resistance to acids, bases and alcohols.