High Performance Polymers/Specialty Molding

Over Molding

Overmolding refers to the process of molding a polymer over a substrate, such as metal or another polymer. The process is an alternative to material bonding, which is generally more costly and time consuming.

Not all substrate materials can withstand the melt temperatures of high performance polymers. Consult with one of China Array's engineers to confirm compatibility.

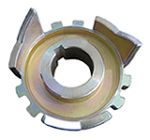

Insert Molding

Insert molding is a variation on over-molding whereby an insert (the substrate) is placed in the mold prior to molding and the polymer is injection molded around it.

Compatible with a variety of substrates, HPP's free flow melt characteristics conform readily to intricate geometries to achieve full packing out of the part and full coverage of the insert.

Micro Molding

Micro molding, generally associated with molding parts weighing less than five grams, also encompasses over-molding and insert molding of miniature components.

Micro molds, especially for high performance polymers , require high heat components, exacting precision and smooth mechanics.

Vertical Injection Molding for Inserts

High efficiency insert molding is best achieved using vertical injection molding machines, such as the Arburg 275V ALLAROUNDER shown at left. Inserts are ergonomically encapsulated during the molding cycle, while another set of inserts is being prepared for the next cycle. China Array's Arburg machines feature high heat molding packages tailored to high performance polymers.

Torlon, PEEK and Ultem, matched with Arburg Vertical molding machines, lend themselves well to insert and over-molding.