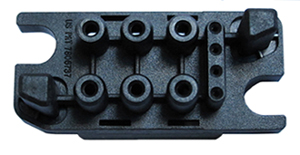

PBT/Small Form Factor Connector Housings

Small form factor connectors provide higher current carrying capabilities, better mechanical and thermal characteristics, and superior electrical performance than larger, conventional connectors of just a decade ago.

Combining hundreds of parallel points of contact and smaller, pure copper conductors, they provide very low resistance, low insertion force and high conductivity: carrying as much or more current (up to 100 A) with low voltage drop in a smaller form-factor package.

High Volume Precision Molding

These smaller connectors require more complex, thin walled housings, and, as with most connector projects, volumes are large. Robust, reliable and precise multi-cavity tooling is essential, as is consistent injection molding processing.

China Array has developed tooling and processing for dozens of small form factor connecter housings that hold tight tolerances while producing at high volume rates: many running "lights out" around the clock.